just cnc store

A11E 4-axis linkage motion control system Rich Auto DSPcnc engraving motion controller laser, flame, plasma cutting machine

Couldn't load pickup availability

Product List:

Handle*1

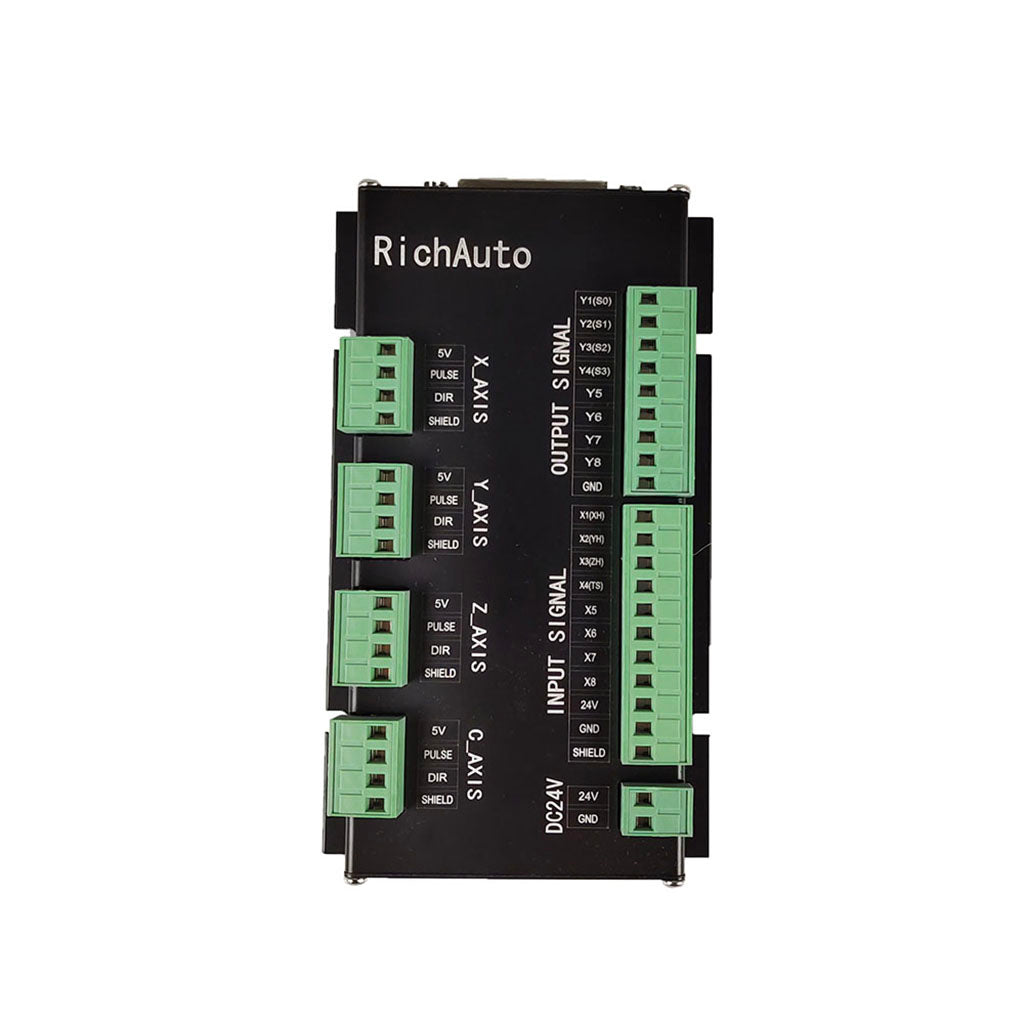

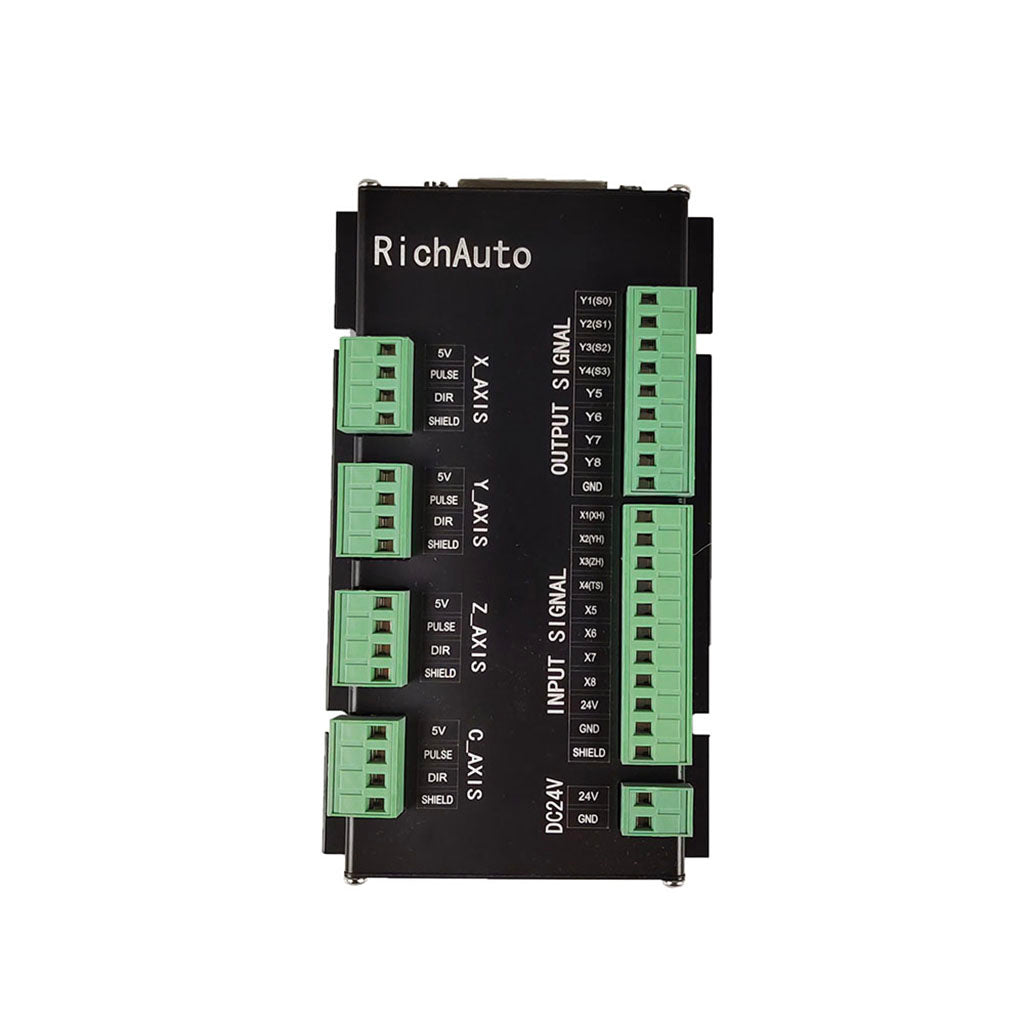

Patch panel*1

USB cable*1

50-pin signal line*1

introduction:

The RichAuto control system is an independent engraving machine motion control system developed by Beijing Reiz Tianhong Technology Co., Ltd.

Used in machinery, advertising, woodworking, mold engraving machines, laser, flame, plasma cutting machines, and other industries in the field of machine tool control.

The RichAuto control system is based on DSP, and the high-speed computing processing speed is a single-chip microcomputer.

Proposed; embedded structure, high degree of integration, strong stability, easy to install and operate; support U disk, card reader mobile

Storage, using USB interface communication, fast transfer speed, plug and play fully realize full offline work.

Performance characteristics:

- System standard configuration X, Y, Z are three-axis motion control mode, support rotary axis (C axis) control, can achieve rotation plus

Work and plane machining switching; can be extended to X, Y, Z, C four-axis motion control to achieve four-axis linkage control.

- Multiple I/O point control mode, basic I/O signal nodes each have 8 input and output signals, and the extended I/O node can be expanded to 32 input and output signals.

- Support standard G code and PLT format instructions; support mainstream CAM software at home and abroad, such as Type3, Artcam, UG, Pro/E, MasterCAM, Cimatron, Wentai and other software.

- With power-down protection. When the processing is interrupted, the system automatically saves the current processing letter (file name, current processing line number, machining speed, spindle gear position). After power-on again, the system automatically prompts the user to resume machining before power-off. The operation has become more user-friendly.

- Support breakpoint memory and file selection processing. 8 different breakpoint machining information can be saved.

- Multi-coordinate system memory function. With 9 working coordinate systems, users can switch between 9 jobs, and each coordinate system can save a machining origin information.

- Support the adjustment of the spindle running frequency during machining (or directly write the spindle speed). It can be set to 1 to 8 eight gear positions as needed, and the gear position can be adjusted by pressing the button during machining without stopping the machining.

- Supports adjustment of machining speed during operation. The user can adjust the machining speed and the idle speed by pressing the button to adjust the machining speed.

The speed and speed override values are incremented or decremented by 0.1 each time from 0.1 to 1.

- Simple manual mode of operation. The system provides continuous, step (jog) and distance movement modes in manual mode, and the manual operation becomes more concise and convenient.

- It can recognize extended instructions such as M code and F code, and can open special code according to user requirements.

- Built-in 512 M memory.

- The unique hand-held form factor can be held with one hand. With its own LCD display and 16-key operation keyboard, the operation is intuitive and flexible, no longer dependent on the

Multiple operations

Automatic tool change

Easy to install

easy to use

Multi-blade simultaneous processing

Easy to debug

DPS processor

Maximum pulse 1M/S

Stepper servo universal

Support for differential signals,

fiery

Marketing

Panic buying

A11E handle features

Special handle for engraving machine English manual for easy operation Easy installation

Size description

Share